manual centrifuge

A manual centrifuge is a laboratory device used to separate substances of different densities through centrifugal force. It is commonly used for processing biological samples.

1.1 What is a Manual Centrifuge?

A manual centrifuge is a device designed to separate substances of varying densities using centrifugal force. It operates manually, requiring human intervention to spin samples. Unlike automated centrifuges, manual models are often simpler, more portable, and cost-effective. They are commonly used in laboratories and clinical settings for tasks like separating blood components or processing small biological samples. The device typically consists of a rotor, sample tubes, and a handle for manual operation. Manual centrifuges are ideal for low-volume, precise separations where automation is not necessary. They are widely used in educational, research, and diagnostic applications due to their ease of use and versatility.

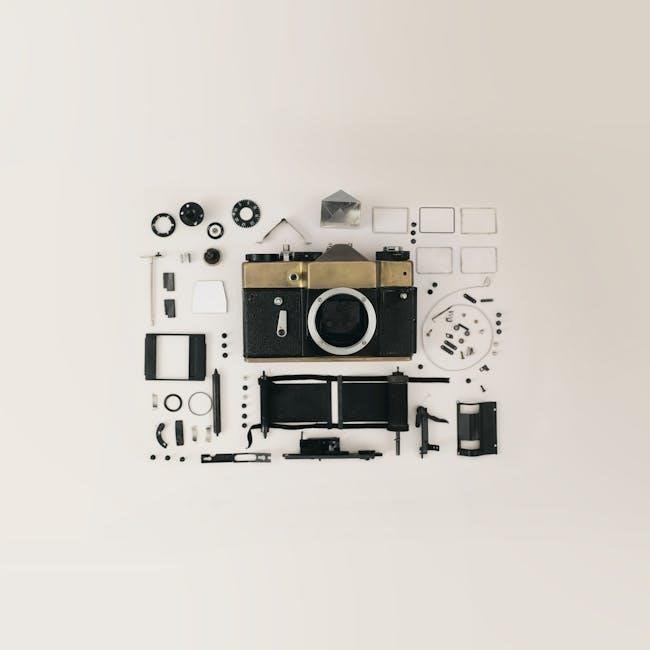

1.2 Key Components of a Manual Centrifuge

The key components of a manual centrifuge include a rotor, sample tubes, a handle, and a lid. The rotor holds the sample tubes securely during operation. The handle allows manual spinning, generating centrifugal force. The lid ensures safety by preventing accidental opening. Some models feature adjustable speed controls and a base for stability. These components work together to enable efficient separation of substances based on density. Regular maintenance of these parts is essential for optimal performance and longevity of the device. Understanding each component’s function is crucial for proper operation and safety when using a manual centrifuge in laboratory or clinical settings.

Working Principle of a Manual Centrifuge

A manual centrifuge operates by generating centrifugal force through manual spinning, separating substances of varying densities within sample tubes placed in a rotor.

2.1 The Concept of Centrifugal Force

Centrifugal force is the apparent outward force experienced by objects moving in a circular path. In a manual centrifuge, this force separates substances of different densities. When the centrifuge spins, heavier particles move outward, while lighter particles remain closer to the center. This principle is fundamental for isolating components like blood plasma or cellular material. The effectiveness of separation depends on the speed and duration of spinning, making centrifugal force essential for achieving desired laboratory results. Proper balancing of the centrifuge ensures even distribution of force, preventing vibration and ensuring accurate separation. This mechanism is integral to various scientific applications.

2.2 Types of Manual Centrifuges

Manual centrifuges are available in various types, each designed for specific applications. Clinical centrifuges are commonly used in medical settings for blood separation, while research centrifuges are tailored for laboratory use, offering precise control over speed and time. Microcentrifuges, smaller in size, are ideal for processing small sample volumes, such as DNA or protein extractions. Some manual centrifuges are fixed-speed, providing simplicity, while others allow variable speed adjustments. Portable models are designed for fieldwork, offering convenience and ease of use. These centrifuges may also accommodate different rotor types, such as fixed-angle or swinging-bucket rotors, depending on the desired separation efficiency. Their versatility makes them essential tools in diverse scientific and clinical environments.

Safety Guidelines for Using a Manual Centrifuge

Always ensure the centrifuge is properly balanced and placed on a stable surface. Wear protective gear like gloves and goggles. Avoid overloading and follow manual instructions carefully.

3.1 Precautions Before Operation

Before using a manual centrifuge, ensure it is placed on a stable, level surface to prevent vibration or tipping. Always balance the centrifuge to avoid uneven operation, which can damage the device or lead to accidents. Secure all samples properly in their tubes and ensure the lid is tightly closed. Wear protective gear, including gloves and goggles, to safeguard against potential splashes or spills. Inspect the centrifuge for any signs of wear or damage, such as cracks in the rotor or loose parts, and address these issues before operation. Proper training and consultation of the user manual are essential for safe and effective use.

3.2 Best Practices During Operation

During operation, handle the centrifuge gently to avoid sudden jerks or vibrations. Ensure all samples are securely placed in their respective tubes and the lid is tightly closed. Start at a low speed and gradually increase to the desired setting to maintain balance. Monitor the centrifuge for unusual noises or vibrations, which may indicate imbalance or issues. Keep the surrounding area clean and clear of obstacles to prevent accidents. Regularly check the temperature and speed settings to ensure they align with the requirements of your samples. Always follow the manufacturer’s guidelines for maximum load and speed limits. Be prepared to stop the centrifuge immediately if any irregularities occur.

Maintenance and Troubleshooting

Regularly clean the centrifuge after use and inspect for wear and tear. Check rotor balance and replace worn parts promptly to ensure smooth operation and prevent damage.

4.1 Routine Maintenance Tasks

Regular maintenance ensures optimal performance and longevity of the manual centrifuge. Clean the rotor and sample chambers after each use to prevent contamination. Inspect the centrifuge tubes and replace any cracked or worn-out ones. Lubricate moving parts periodically to reduce friction. Check the balance of the rotor and ensure all components are securely fastened. Refer to the user manual for specific maintenance schedules and guidelines. Proper care extends the life of the centrifuge and ensures accurate, reliable results in various laboratory and industrial applications. Regular maintenance also helps prevent unexpected breakdowns and enhances safety during operation.

4.2 Common Issues and Solutions

Common issues with manual centrifuges include imbalance, vibration, and sample leakage; To address imbalance, ensure equal distribution of samples and check for damaged or uneven tubes. Excessive vibration may indicate misaligned rotors or worn-out bearings, which require professional servicing. For leakage, inspect seals and gaskets for wear and replace them as needed. Regular lubrication of moving parts can prevent friction-related issues. Always refer to the user manual for troubleshooting specific models. If problems persist, contact the manufacturer or a certified technician. Proper care and timely solutions can restore optimal functionality and extend the centrifuge’s operational life, ensuring reliable performance in laboratory settings.

Applications of Manual Centrifuges

Manual centrifuges are widely used in laboratories, clinics, and industries for separating blood components, processing biological samples, and various industrial applications, meeting diverse research and processing needs efficiently.

5.1 Laboratory Use

Manual centrifuges are essential tools in laboratory settings, primarily used for separating substances of varying densities. They are frequently employed in biology, chemistry, and medical laboratories for tasks such as blood component separation, DNA extraction, and sample preparation. These devices are particularly useful for small-scale operations, offering precise control over centrifugation parameters. Laboratories often rely on manual centrifuges for their simplicity, cost-effectiveness, and ease of use. They are also utilized in research settings for processing biological samples, such as separating plasma from blood or isolating cellular components. Their compact design and versatility make them indispensable in modern laboratory workflows.

- Separating blood components like plasma and serum.

- Processing biological samples for research.

- Isolating DNA, RNA, or proteins.

- Preparing samples for further analysis.

Regular maintenance ensures optimal performance and safety in laboratory environments.

5.2 Industrial Applications

Manual centrifuges are widely used in various industrial applications for separating substances of differing densities. They are particularly useful in food processing, pharmaceutical manufacturing, and chemical industries. In food production, they are employed for tasks like separating cream from milk or filtering beverages. In chemical plants, they help isolate solid particles from liquids or separate immiscible liquids. Their portability and ease of operation make them ideal for small-scale industrial processes or pilot plants. Additionally, manual centrifuges are utilized in wastewater treatment facilities to remove suspended solids. They are also used in the dairy industry for butterfat separation and in breweries for clarifying beverages. Routine maintenance ensures reliability and efficiency in industrial environments.

- Food processing for liquid-solid separation.

- Chemical manufacturing for immiscible liquid separation.

- Pharmaceutical production for isolating active compounds.

- Dairy industry for butterfat extraction.

Their versatility and simplicity make them a valuable asset in industrial workflows.

Advantages and Disadvantages

Manual centrifuges are cost-effective, portable, and easy to use, ideal for small-scale operations. However, they lack automation, requiring manual effort and offering limited capacity compared to automated models.

6.1 Benefits of Manual Centrifuges

Manual centrifuges offer several advantages, including cost-effectiveness, portability, and simplicity of operation. They are ideal for small-scale laboratory settings or educational environments due to their ease of use and minimal setup requirements. These devices are also energy-efficient and require less maintenance compared to automated models. Additionally, manual centrifuges provide precise control over the centrifugation process, allowing users to adjust settings according to specific needs. Their compact design makes them suitable for limited workspace, and they are often more accessible for laboratories with budget constraints. Overall, manual centrifuges are reliable tools for basic centrifugation tasks, offering a practical solution for separating substances in various scientific applications.

6.2 Limitations Compared to Automated Centrifuges

Manual centrifuges have several limitations when compared to automated models. They lack programmable features, requiring manual adjustment of settings, which can be time-consuming and prone to human error. Automated centrifuges offer higher precision, consistency, and the ability to handle larger volumes, making them more efficient for high-throughput applications. Additionally, manual centrifuges often operate at lower speeds, limiting their effectiveness for certain complex separations. They also require constant user intervention, reducing productivity in busy laboratories. Furthermore, manual models may not include advanced safety features or data logging capabilities, which are standard in automated centrifuges; These limitations make manual centrifuges less suitable for advanced or industrial-scale operations, where automation is crucial for efficiency and accuracy.

Related Posts

onan 4000 genset manual

Need an Onan 4000 genset manual ASAP? Download a reliable guide to troubleshoot, repair, & maintain your generator. Keep the power flowing smoothly!

testo 550 manual

Need a Testo 550 manual? Find everything you need right here – from setup to common fixes! Get back to measuring quickly and accurately. Download now!

smc 3 user manual

Find the official SMC 3 User Manual now! Get detailed instructions and tips to help you get more from your system. Your guide to unlocking all the features of the SMC 3 awaits.